-

2025-03-13

- 0 Comment

ULTRA HYGIENIC® Stainless Steel Ball Valve

Ball valves are an integral part of any cleaning system, as their reliability and tightness are crucial for the proper functioning of the system. The reliability and quality of the valves also affect the comfort and safety of the workers and the water consumption during the cleaning processes.

The ULTRA HYGIENIC® valve is made entirely from acid-resistant stainless steel (it is also equipped with PTFE seals). Stainless steel is the ideal material for equipment requiring the highest hygiene standards, as it is resistant to all types of contaminants, acids, and bases.

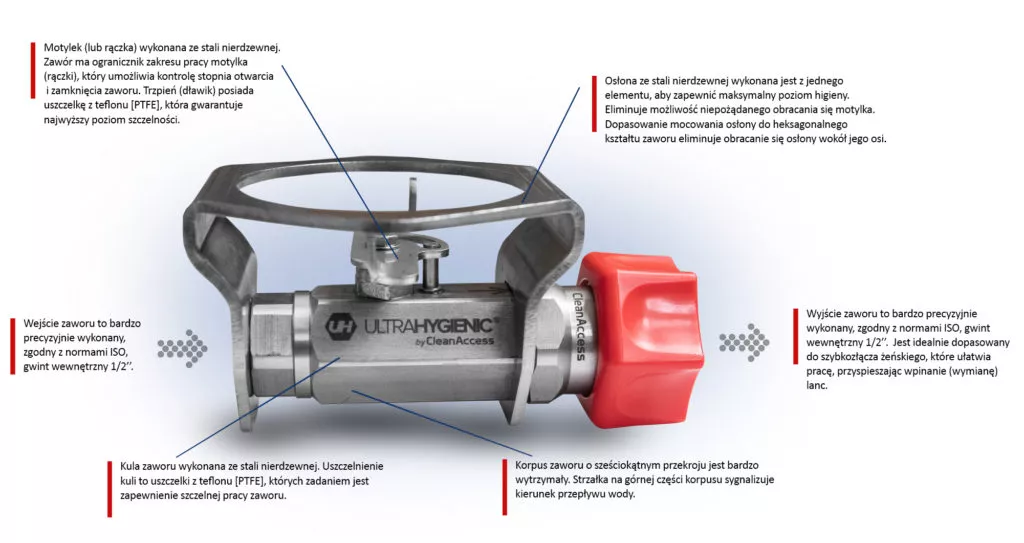

ULTRA HYGIENIC® Valve Construction

The mechanism of ball valves involves effectively cutting off the water flow by rotating the ball with a hole in the valve seat. Water flowing through the hose or pipe has either an open or closed flow, which means that ball valves are not designed to regulate the flow strength. Due to their construction, ball valves are resistant to contamination and dirt. They are characterized by durability and tightness.

The valve body is tight and well-balanced. The hexagonal shape stabilizes it on inclined surfaces. An arrow on the top of the valve body indicates the direction of the water flow.

The valve’s entry and exit are made with a precisely manufactured internal thread (1/2’’) that ensures a flat seal according to ISO standards. Threaded elements with a conical seal can also be used (by applying mounting glue or a cleaner). Both threads are compatible with the ULTRA HYGIENIC® female quick connector, which facilitates work by speeding up the insertion (replacement) of lance elements. The quick connector can also be used to connect the valve to a mounting bracket. A valve hanging freely from the hose can pose a safety risk to workers.

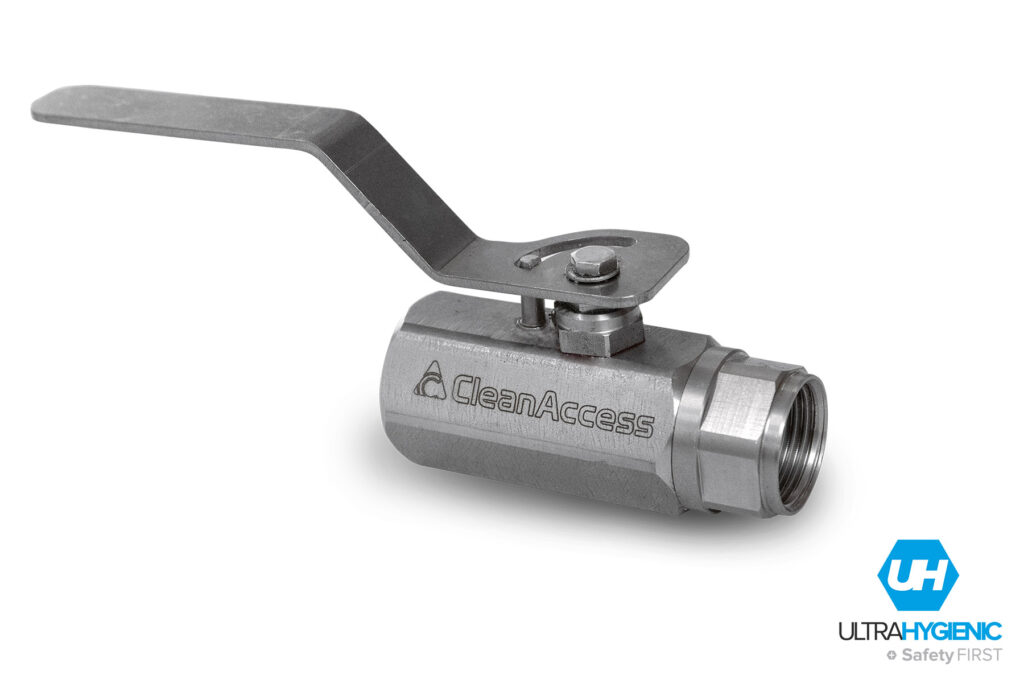

The valve ball is made of stainless steel, and its sealing is done with PTFE seals, which ensure optimal valve performance. The butterfly (or handle) is made of stainless steel. The valve has a limiter for the butterfly (handle) range, allowing control over the degree of opening and closing the valve. The stem (seal) has a PTFE seal, which guarantees the highest level of tightness.

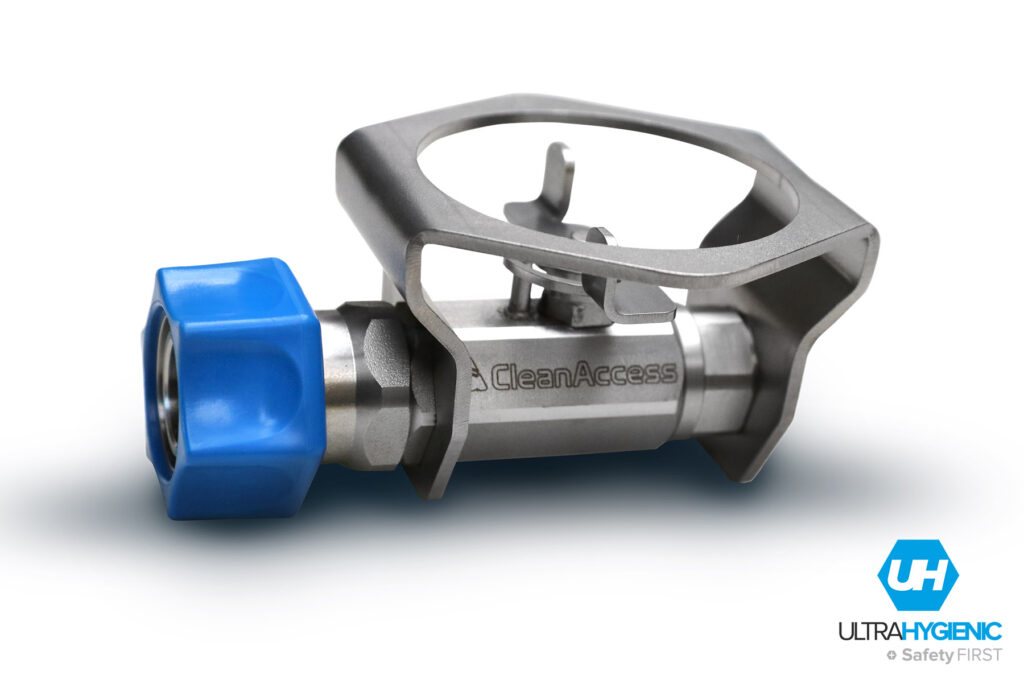

The stainless steel cover is made from a single piece to ensure maximum hygiene. It eliminates the risk of the butterfly spinning unintentionally. The cover’s fitting to the valve’s hexagonal shape prevents it from rotating around its axis.

Applications of ULTRA HYGIENIC® Valves

The ULTRA HYGIENIC® valves are small in size and low in weight, making them easy to operate and maintain. They can be used for fluids with a temperature of up to 95°C and a maximum pressure of 60 bar.

The ULTRA HYGIENIC® valve can be used as a shut-off or flow valve. The model with a handle is ideal for installations, while the model with a butterfly is perfect for use at the end of the hose. Regardless of whether it aids in the process of water flushing, disinfection, cleaning, or foaming with a chemical agent, it performs its role excellently.