-

2025-03-13

- 0 Comment

Color-Coding Zones

What should you know about color-coding?

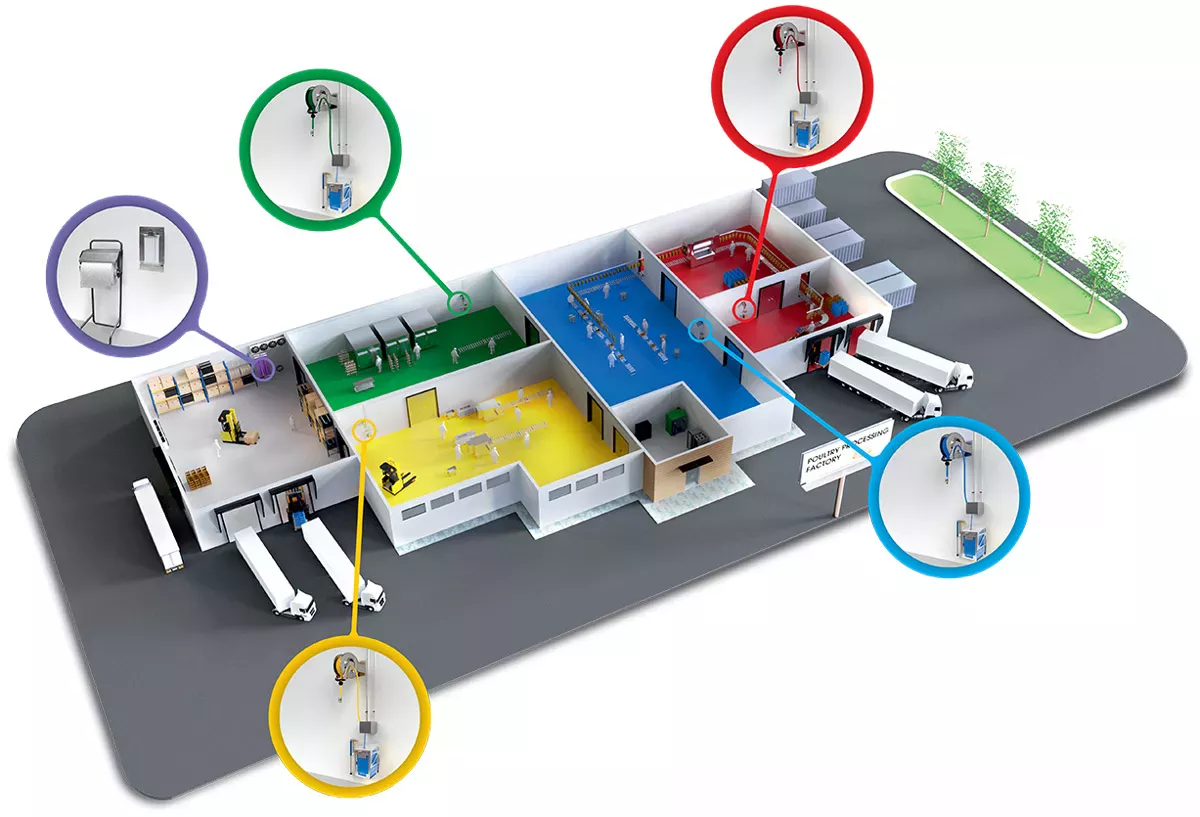

Color-coding is an essential part of every food safety program. It helps prevent cross-contamination due to pathogens, allergens, and foreign contaminants. It also has many other applications. As hygiene requirements increase, it is important for food processing plants to stay up-to-date with best practices to become market leaders and eliminate risks. Implementing a color-coding program is an excellent way to achieve this.

- Any type of food processing plant can benefit from a color-coding system.

- Color-coding helps prevent cross-contamination in food processing plants.

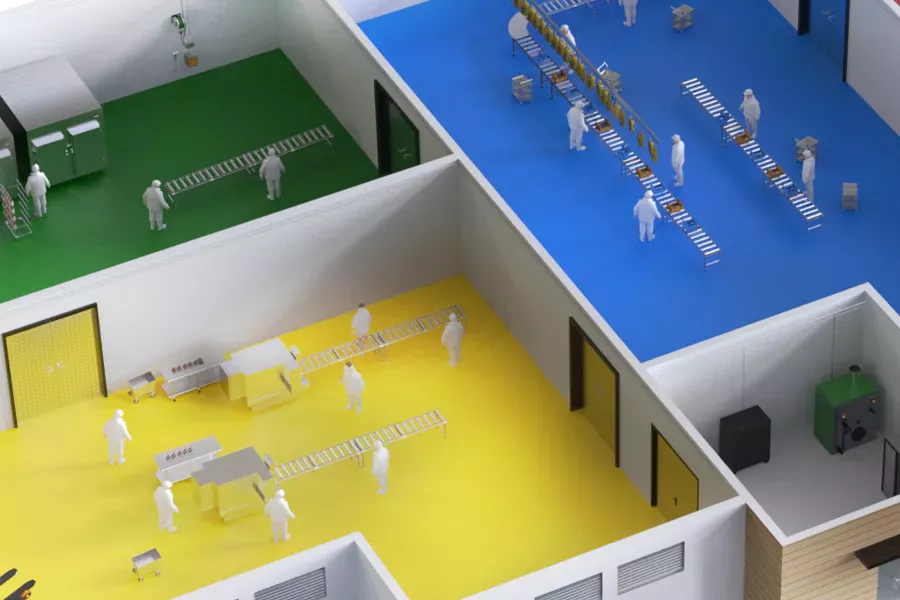

- Color-coding makes it easier to distinguish hygiene zones.

- Color-coding programs are positively evaluated by auditors and clients.

Color-Coding Zones

RULES FOR IMPLEMENTING COLOR CODING:

- Limit the number of colors to 3-5 in small or medium-sized facilities.

- Choose contrasting colors for adjacent zones to avoid confusion.

- Assign colors to products—red is quickly associated with tomatoes, but if someone drops a tool into the product, it will be harder to spot.

- Avoid using complex color combinations—use one color per zone. Immediate recognition is one of the greatest advantages of color-coded tools.

- Laser marking of tools to enhance and/or complement information. Laser marking eliminates ambiguity and errors, especially in companies employing workers with color vision impairments (color blindness).

- Launch the program for the entire plant at once, not just for part of it. Implement all tool changes at the same time, along with an informational program for employees. Only then can all risks be eliminated and it can be confirmed whether color-coding works and brings benefits.

- Consistently enforce the use of the color-coding program.